Research & Innovation

Research & Innovation

Research & Innovation

Research & Innovation

Research & Innovation

Research & Innovation

Digital Fabrication

Procedure for assistance requests

The e-mail should include the following information:

- Project brief

- Project supervisor

- Name and ID of students in the project

- Schedule of visits

- CAD (STL, DXF, etc) attached

- Consumables required (Amount and type)

- Training requirements (if any)

Digital Fabrication Space

Policies for the use of the equipment

- Students working on the projects should be accompanied by authorized supervisors at all times.

- Authorized supervisors can access the lab during previously scheduled meetings, as long as they communicate properly with the supervisor in place.

- In case a part is missing/broken, an incident report should be created.

- The workspace should be kept tidy. Users should pick up any leftover material/ filament, empty packages and waste after every lab session.

- Food and beverages should not be consumed around the digital fabrication area.

- A record of entries dates, times and activities should be kept on a log book. Students and staff should wear Protective Protection Equipment and keep all covid-19 safety guidelines.

- Working hours: the innovation lab is open from 8:00 AM to 4:00 PM

Equipment

XYZ Da Vinci

- 3D printers for Prototyping of products, complex engineering parts.

- Open Standard (filament, slicing)

- Laser-engraving and scanner

- Single-extrusion FDM (PLA, ABS, PET, TPU, Nylon )

Brother Scan & Cut

- Scan any printed design

- Automatically creates Vector file

- Cut any soft material up to 3mm.

- Carboard , foam, fabrics, plastics

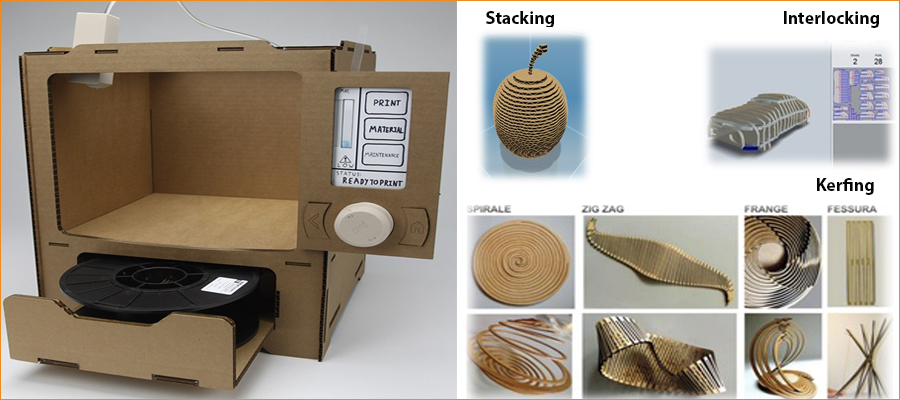

Muse Laser cutter

- Fast prototyping using cardboard, wood, acrylic, leather and other low-cost material options.

- Easily create 3d structures by stacking, interlocking or advanced kerfing.

Sense 3D Scanner

Gives users the ability to observe a scene in three dimensions and then translates the observations into multiple depth images. It then takes combines those depth frames into a 3D model made up of thousands of connected triangles, called a mesh.

- Field of view 57.5 x 45

- VGA depth map (640 x 480)

- USB 2.0

- Color

- Standard off the shelf components

- OpenNI compliant

Autodesk Inventor

Autodesk Inventor is professional level CAD software used for product design and engineering, including 3D mechanical design, simulation, tool creation, and design communication. With Inventor, you can save time and expense when making products. The parametric Inventor 3D digital model enables the design to be validated on-the-fly under real-world conditions for form, fit and function without needing to build a prototype. Simulation of motion, deflection and stress allows you to optimize the product design. Direct editing and advanced surface modeling features enable the creation of intelligent product components.

Cardboard 3D Mockups

Cardboard 3D mockups allow the exploration of usability concepts to facilitate communication, validate design specifications and get feedback before moving on to more advanced prototyping materials and resources.

Abu Dhabi Campus

P.O.Box 111499,

Abu Dhabi,

United Arab Emirates

Al Ain Campus

P.O.Box 66844,

Al Ain,

United Arab Emirates

e-Services

Last Updated Date : November 29, 2022